Automatic Solid Liquid Separator Mechanical Bar Screen For

Wastewater Treatment

Product Description

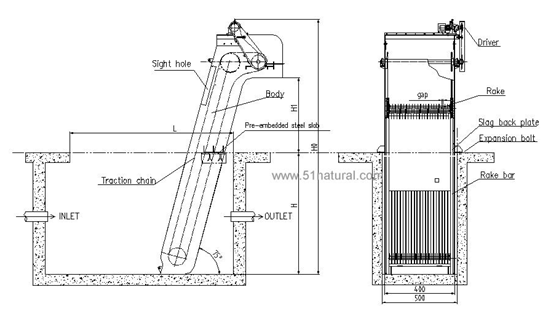

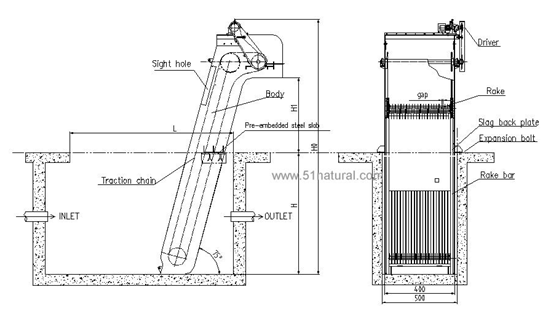

Mechanical toothed harrow mud cleaner machine rake bar screen is a

kind of advanced solid-

liquid separation device in water treatment, which can continuously

and automatically remove

debris from wastewater for sewage pretreatment. It is mainly used

in municipal sewage

treatment plants, residential quarters sewage pretreatment devices,

municipal sewage

pumping stations, waterworks and power plants, also it can widely

be applied to water

treatment projects of various industries, such as textile, printing

and dyeing, food, fishery,

paper, wine, butchery, curriery etc.

Features

♦ The driving unit is directly driven by cycloidal gear reducer or

helical gear reducer which

shows the nature of working stability, low noise, big load

capability and high efficiency in

conveying.

♦ Simple structure with compact size, easy to install and move.

Device can self-clean up

while working, easy to maintain.

♦ Easy to operate, can be controlled directly on the spot or

remote.

♦ Include overload protection device, machine will shut down

automatically when

malfunction happens to avoid damage.

♦ When the device width exceeds 1500mm, will be made into parallel

machine to ensure the

overall strength.

Technical parameters

| Model | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 |

| Drum Diameter(mm) | 600 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 |

| Drum Length I(mm) | 500 | 620 | 700 | 800 | 1000 | 1150 | 1250 | 1350 |

| Transport Tube d(mm) | 219 | 273 | 273 | 300 | 300 | 300 | 360 | 500 |

| Channel Width b (mm) | 650 | 850 | 1050 | 1250 | 1450 | 1650 | 1850 | 2070 |

| Max Water Depth H4 (mm) | 350 | 150 | 540 | 620 | 750 | 860 | 960 | 1050 |

| Installation Angle | 35° |

| Channel Depth H1(mm) |

600-3000 |

| Discharge Height H2(mm) |

Customized |

| H3(mm) | Confirmed by type of reducer |

| Installation Length A(mm) |

A=h*1.43-0.48D |

| Total Length L (mm) | L=H*1.743-O.75D |

| Flow rate(m/s) | 1.0 |

Volume (m3/h) | Mesh (mm) | 0.5 | 80 | 135 | 235 | 315 | 450 | 585 | 745 | 920 |

| 1 | 125 | 215 | 370 | 505 | 720 | 950 | 1205 | 1495 |

| 2 | 190 | 330 | 555 | 765 | 1095 | 1440 | 1830 | 2260 |

| 3 | 230 | 400 | 680 | 935 | 1340 | 1760 | 2235 | 2755 |

| 4 | 235 | 430 | 720 | 1010 | 1440 | 2050 | 2700 | 3340 |

| 5 | 250 | 465 | 795 | 1105 | 1575 | 2200 | 2935 | 3600 |

Model

Parameter | HLCF-500 | HLCF-600 | HLCF-700 | HLCF-800 | HLCF-900 | HLCF-1000 | HLCF-1100 | HLCF-1200 | HLCF-1300 | HLCF-1400 | HLCF-1500 |

| Flow Depth H3(m) | 1.0 |

| Flow Velocity V2(m/s) |

0.8 |

Grid Spacing B(mm) | 1 | Flow Rate Q (㎡/s) | 0.03 | 0.04 | 0.05 | 0.06 | 0.07 | 0.08 | 0.08 | 0.09 | 0.10 | 0.11 | 0.12 |

| 3 | 0.07 | 0.09 | 0.10 | 0.12 | 0.14 | 0.16 | 0.18 | 0.20 | 0.22 | 0.24 | 0.26 |

| 5 | 0.09 | 0.11 | 0.14 | 0.16 | 0.18 | 0.21 | 0.23 | 0.26 | 0.28 | 0.31 | 0.33 |

| 10 | 0.11 | 0.14 | 0.17 | 0.21 | 0.24 | 0.27 | 0.30 | 0.33 | 0.37 | 0.4 | 0.43 |

| 15 | 0.13 | 0.16 | 0.20 | 0.24 | 0.27 | 0.31 | 0.34 | 0.38 | 0.42 | 0.45 | 0.49 |

| 20 | 0.14 | 0.17 | 0.21 | 0.25 | 0.29 | 0.33 | 0.37 | 0.41 | 0.45 | 0.49 | 0.53 |

| 25 | 0.14 | 0.18 | 0.22 | 0.27 | 0.31 | 0.35 | 0.39 | 0.43 | 0.47 | 0.51 | 0.55 |

| 30 | 0.15 | 0.19 | 0.23 | 0.27 | 0.32 | 0.36 | 0.4 | 0.45 | 0.49 | 0.53 | 0.57 |

| 40 | 0.15 | 0.20 | 0.24 | 0.29 | 0.33 | 0.38 | 0.42 | 0.46 | 0.51 | 0.55 | 0.6 |

| 50 | 0.16 | 0.20 | 0.25 | 0.29 | 0.34 | 0.39 | 0.43 | 0.48 | 0.52 | 0.57 | 0.61 |